TECHNICAL DESCRIPTION OF OTHER REHABILITATION METHODS – REHABILITATION OF DRAINS USING HAT PROFILES

in accordance with PN-EN 752-5; 13689; 13566-8 and PN-EN ISO 11296-1 and 11296-4

DESCRIPTION OF METHOD

The Drain LCR (Lateral Connection Repair) Liner system is used to rehabilitate and ensure a permanent seal between the main pipe and connector pipes and laterals leading to house connections of a diameter of up to 300 mm. For that purpose one can choose either LCR hat profiles or LCR liners. An LCR hat profile seals a connection between two pipes in the main pipe using only the edges, while an LCR liner is made in the main pipe, just like a short liner.

LINER INSTALLATION EQUIPMENT

- sewer cleaning machine (jetting truck)

- sewer inspection camera

- compressor

- power generator

- EPROS LCR machine

REHABILITATION PROCESS OF LATERAL CONNECTIONS

Using the LCR machine one can rehabilitate the inlet of a house drain into the main sewer with the use of a so-called short liner. At the same time one can rehabilitate a predefined section of the house drain, or one can install an LCR hat profile. This is performed with a preformed, extensible hose, which is a profiling element. The hose, which on the side surface has a cylindrical shape (packer hose) for the main pipe, has a centrally located additional cylinder (connector pipe hose) set at a 45° or 90° angle.

The side connector pipe hose is inserted before the rehabilitation into the packer hose together with the LCR liner or LCR hat profile which have the same form of the profiling element. Then, air is deflated from the packer hose and connector pipe hose. This ensures that the material for the rehabilitation (LCR liner or LCR hat profile) does not slip off the required place.

The machine is placed at the rehabilitation point with the use of a fiber glass rod and 2 telescopic wheel assemblies. The unit can be rotated axially at the point of the rehabilitation using the wheel assemblies and a rotation drive. A camera mounted on the machine helps position it precisely.

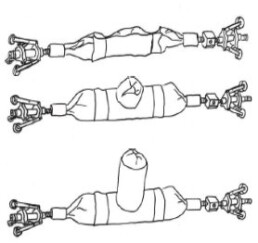

LCR System

A. Empty packer hose before insertion

B. Packer hose partially inflated with air after its position has been fixed

C. Packer hose fully inflated with air, with installed LCR liner

Then from a control panel the expansion mechanism (pathfinder) is positioned. It lifts a basket and presses an integrated brim against the pipe wall. Following the above, the packer is withdrawn with the fiber glass rod and the brim is slid into the lateral opening. However, if the outlet opening cannot be found the machine can be repositioned so that the expansion basket slides into the lateral opening.

Once the positioning is finished the packer hose is inflated, the connector pipe hose with the liner is inserted into the house lateral and the basket withdraws. The insertion delay is achieved with a high strength line, which is driven and slowed down by a winch. A sound signal confirms the completion of the insertion into the lateral. After curing the liner, air is deflated from the machine and it can be removed from the rehabilitation point.

KEY ADVANTAGES OF THE SYSTEM

Reliable installation method:

- Insertion takes place only when the LCR basket is properly positioned.

- The sound signal goes off only after the insertion has been completed.

–Technical advantage: rehabilitation along bends and when pipes are dislocated can be achieved only with the insertion method.

– Meets practical requirements: successful rehabilitation possible also in the presence of ground water, with little equipment required.

– Cost efficiency: small investment cost, as only required packers are purchased.

– Practical: light-weight, mobile machine, can be transported also on a light truck.

– Flexibility: repair can be carried out using a pneumatic push rod or wheel assembly.

– Availability: LCR packers can be positioned pneumatically at an angle which helps in axial insertion of LCR packers into the sewer

APPLICATION

Gravity sewer networks.